Chaconne

Well-known member

- Likes

- 91

- Location

- Massachusetts

This is rather common on European machines. It is poor attention to detail. My 2020 KTM is terrible when it comes to water sealing in almost every aspect fuel, electrical, & etc.I have to add that I think it's a major design flaw to have a huge opening on the upper triple clamp that feeds water to a somewhat sealed wiring box below. What on earth were they thinking??? They might as well make the box open beneath so it at least drains. My solution will be to make a silicone plug that perfectly fits that hole up top. Every time you wash the bike water goes there!

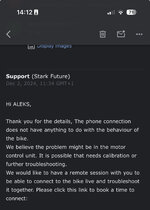

Initially I thought Stark was going to take a different approach when they said the bike could be powerwashed but that was retracted and you have to be very careful to seal off junctions, connections, and wiring.

Also switches are not well sealed on the Stark either, the main power switch is very susceptible to both dirt and water intrusion. I have been stranded due to it. My 2014 Yam WR450 has great water sealed switches and is more water tight than either newer KTM or Stark.

In Stark's defense the first versions were MX bikes which would likely be used on a closed track so getting stranded miles away from a carrier was probably not a first consideration. I have used my bike as an Enduro so the handlebars going full depth in mud and water probably wasn't a first design consideration. But from @Aleksandar13 's reports seems there are still some openings even on gen 2.