You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Alta throttle - all there is to know

- Thread starter Oded

- Start date

- Likes

- 4,502

- Location

- Lake Havasu City, AZ

An overkill is good when you have 50-80 horses between your legs and you are relying on being able to control them properly to accelerate and clear a big jump and then slow down and not launch off a bowl turn's berm into the grandstands. Can't have accidents like this happen due to a loose wire or some silly single potato chip malfunction. Else, riders will sour on the throttle-by-wire technology and go back to the iron age.

This guy have a YouTube channel where he reviews, from an electrician's point of view, different DIY emotorcycles components. He is great.

However, he is mostly into homebuilt & Surron type components, and not Alta & Stark specs. That's why he is surprised at the super high quality of this throttle. He is not used to it in my opinion.

However, he is mostly into homebuilt & Surron type components, and not Alta & Stark specs. That's why he is surprised at the super high quality of this throttle. He is not used to it in my opinion.

EDR1

Member

- Likes

- 24

- Location

- San Francisco

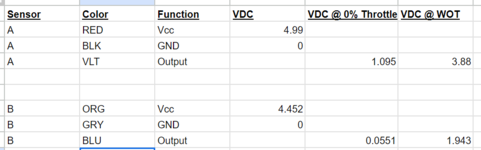

Excellent teardown. The 2-sensor design might be used for redundancy AFTER startup checklist but BEFORE startup, it is used as a parity check to confirm throttle position. Both sensors are required to work or the ACM will not pass the startup checklist. Here is a link to their datasheet: https://www.hirschmann-automotive.com/downloadFile/304 and here are the pinouts and voltages:Here is a Alta (Hirchmanm) throttle tear down by an electrician. He explains well what differ it from other throttles -

EDR1

Member

- Likes

- 24

- Location

- San Francisco

Number Six

Well-known member

- Likes

- 146

- Location

- Midwest

Anyone who made it past the 5 or 6 minute mark deserves a medal & would be a good special ops candidate for their proven ability to withstand even the worst of interrogation tactics.

..

..

Trialsman

Well-known member

- Likes

- 601

- Location

- Pittsburgh

OK, so the idea I wanted to explore is to interrupt the signal wire/wires back from the throttle to the ECU. I wanted to pass them through another "throttle" on a lever to make an electric clutch. This would be so handy ( no pun intended ) for lofting the front end for obstacles in rough single track. The lever would provide precise deployment of power, as opposed to the gross motor skills of a wrist throttle only. Any ideas?

EDR1

Member

- Likes

- 24

- Location

- San Francisco

I don’t see that working even if the Alta safety checks were bypassed because a real clutch works by capturing the flywheel action of the motor which is a lot more instantaneous power than the power band of electric bikes w/o that feature. My workaround is to keep the stock MXR 12T/53T gear ratio for good wheel torque, (or possibly go to 11T/53T) stay in Map4 , flick the throttle and use appropriate body English as needed. That’s a long way of saying it’s cheaper to buy a bike designed to do that. If you like trials riding then look at Electric Motion.OK, so the idea I wanted to explore is to interrupt the signal wire/wires back from the throttle to the ECU. I wanted to pass them through another "throttle" on a lever to make an electric clutch. This would be so handy ( no pun intended ) for lofting the front end for obstacles in rough single track. The lever would provide precise deployment of power, as opposed to the gross motor skills of a wrist throttle only. Any ideas?

Number Six

Well-known member

- Likes

- 146

- Location

- Midwest

The terms ; 'interrupt the signal' & 'precise deployment of power' would seem contradictory as signal interruption is on / off by definition.

Clutches on the other hand meter power as gradually or quickly as desired via the amount & speed of lever movement imparted by the user.

Maybe if a 2nd throttle device or lever incorporated some sort of fast acting, short throw rheostat one could emulate the action of a traditional mechanical clutch ?

Electric Motion's solution is indeed a mechanical clutch, one would think if it could've been done electronically, they'd be the ones to pull it off ;

Clutches on the other hand meter power as gradually or quickly as desired via the amount & speed of lever movement imparted by the user.

Maybe if a 2nd throttle device or lever incorporated some sort of fast acting, short throw rheostat one could emulate the action of a traditional mechanical clutch ?

Electric Motion's solution is indeed a mechanical clutch, one would think if it could've been done electronically, they'd be the ones to pull it off ;

Trialsman

Well-known member

- Likes

- 601

- Location

- Pittsburgh

If I am interrupting the signal with ANOTHER Hall effect unit it should be metered - not on/off.

Number Six

Well-known member

- Likes

- 146

- Location

- Midwest

Incorporated into a lever somehow ? That'd be great.

Maybe it'd be able to be used on several different E-bikes ...

If you were to succeed - patent that thing & enjoy the royalties from licensing that holy grail of e-bike drive trains to OEM's !

Maybe it'd be able to be used on several different E-bikes ...

If you were to succeed - patent that thing & enjoy the royalties from licensing that holy grail of e-bike drive trains to OEM's !

I'd like to share an experience of mine with Hall sensors.

Some years ago I borrowed an idea from a video in which F1 drivers trained to think sharply even with high heart rate and physical demand, typical of racing: I made up this workout in which I keep my heart rate in zone two with a stationary bike and at the same time I play a racing simulator with a laptop in front of me: the idea is that I keep my brain trained to think sharply and react quickly even under physical demand of supermoto, motocross and occasional rental karting. Since I play a little bit of flight simulators, I started using a flight sim joystick (coudn't use wheels and pedals anyways on a stationary bike), but that first joystick didn't last much, probably also because of the sweat damaging the potentiometers: I clean the outside surfaces after every use, but I'm not willing to disassemble it every time to dry the components inside. Then, I think at least since 2018, but most likely way before that, I replaced it with a Thrustmaster T16000 M joystick with Hall sensors for the pitch and roll axes and a potentiometer for the throtte axes; to play the racing sim, I only utilize the pitch and roll axes equipped with Hall sensors. The conventional potentiometer for the throttle quickly failed because of the sweat and cleaning it with alcool repaired it for a little while but then it started failing again. The Hall sensors have never failed. That joystick is now prety worn and it has a lot of mechanical play, but the axes controlled via the Hall sensors have never been erratic and are still perfectly reliable.

Some years ago I borrowed an idea from a video in which F1 drivers trained to think sharply even with high heart rate and physical demand, typical of racing: I made up this workout in which I keep my heart rate in zone two with a stationary bike and at the same time I play a racing simulator with a laptop in front of me: the idea is that I keep my brain trained to think sharply and react quickly even under physical demand of supermoto, motocross and occasional rental karting. Since I play a little bit of flight simulators, I started using a flight sim joystick (coudn't use wheels and pedals anyways on a stationary bike), but that first joystick didn't last much, probably also because of the sweat damaging the potentiometers: I clean the outside surfaces after every use, but I'm not willing to disassemble it every time to dry the components inside. Then, I think at least since 2018, but most likely way before that, I replaced it with a Thrustmaster T16000 M joystick with Hall sensors for the pitch and roll axes and a potentiometer for the throtte axes; to play the racing sim, I only utilize the pitch and roll axes equipped with Hall sensors. The conventional potentiometer for the throttle quickly failed because of the sweat and cleaning it with alcool repaired it for a little while but then it started failing again. The Hall sensors have never failed. That joystick is now prety worn and it has a lot of mechanical play, but the axes controlled via the Hall sensors have never been erratic and are still perfectly reliable.