TonyWilliams

User asked to be "deleted"

- Likes

- 172

- Location

- San Diego, California USA

1) The Alta's pack arranges the cells as densely as possible. This is both good and bad. Good from a capacity per volume perspective but not so good thermally.

Pretty standard automotive arrangement for cylindrical cells, made popular by Tesla. Even the tiny wire “fuseable” link seems to be a Tesla automotive concept.

2) The Alta's "passive" thermal control system does little during an initial (from ambient) high amperage discharge cycle, less than 15 minutes to thermal limiting (an A level rider discharge profile, for example).

I think calling this a cooling system is being generous.

3) The Alta's "passive" thermal control system can help delay the onset of thermal limiting during less aggressive discharge drive cycles AND can help reduce cell temperature between charge/discharge cycles, but not by much. Once the cells are "heat soaked" it's very difficult to pull the energy back out, even with fans, etc.

Very dense cells will absolutley stay hot once heat soaked, which is why I’m not confident that a non-liquid cooling medium will perform the needed task of somewhat quickly reducing the cell temperature in potentionally high ambient temperatures.

4) Any "wet" thermal solution would need to flow axially, as the physical proximity between cells restricts efficient and effective radial flow. The nature of the packaging design pretty much makes an axial flow solution virtually impossible.

I’m not sure that I’m following, but then I haven’t pulled mine apart yet (I actually haven’t received the bike yet).

5) An externally cooled "cold plate" mounted between the individual module and the radiator housing does well up a point, but the delta temp between keeping the cells internal temperatures at or below my cutoff point and the ambient temperature is narrow. To work efficiently at higher ambient temperatures would mean adding very large external radiators and the weight hit and complexity just wouldn't be worth it.

Yes, I concur that the Temperture delta between ambient (40-45C possible) and cell limit of 50-52C is just not something that could be passively done, nor is a air to liquid heat exchanger (radiator) going to work in a small and lightweight size.

I’m thinking that a good cold soaking at 15-20C between motos with a little dry ice (frozen CO2) on a cooling plate should get through a moto. How to incorporate that might require a new battery case. Maybe the dry ice fits inside the heat sink?

Given 1-6, I've concluded that the best strategy (for me) would be the following;

1) Incorporate a cell with a higher discharge rating than the Sony and take the hit in capacity.

You could just add more cells (and weight) to compensate?

2) Throw away the Alta closed composite cell housing in favor of an "exposed cylindrical surface" support structure and design in a source of "forced air" cooling.

That would be interesting.

3) Design an alternative hot gas "venting" route.

I would be afraid of moisture, dirt, FOD, etc, from getting in the battery case.

4) Incorporate two "cold plates" for use between motos only to reduce core cell temperatures to approx. 10C below ambient (to about 50F). Along with a modest cell upgrade and some forced air cooling, this temperature should provide enough headroom to prevent thermal limiting even under extreme conditions. The rate of heat removal is as important as heat generation so further analysis is required in this area.

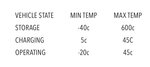

You really don’t want the cells at 10C to start a race... 15-20C minimum, I think. Another strategy is to let the cells get hotter than 50-52C (or whatever threshold that ALTA has programmed for power limiting. They aren’t likely to blow up at 55C, for instance, but you’ll definitely start affecting long life with the hotter you get. I’d probably make an absolute 58-60C shutdown.