wwmotors

Well-known member

- Likes

- 459

- Location

- Bavaria Germany

Yesterday i got my first code or problem on my 2018 MXR (code 37) after +6000 MX kms. Strange: The bike was standing dry for weeks, never got washed the last weeks, because in the MX hall it is not really dirt sticking to the bike. Then after 2 weeks of storing in the house at 10-15 degrees Celsius, I did 6 stints with 10 minutes in the MX hall. Drove the bike home in the closed van. When riding the bike slowly into my house, the code came up!

My explanation: The humidity was already there. When the bike cooled down in the back of the van to nearly 0 degrees Celsius, the relative humidity went up over the critical barrier. Is there any tutorial from other guys here, how to change the desiccant pack (descrition, pistures , Youtube video etc...) ?

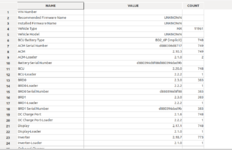

First i will check data with MT and keep You posted, what the datas say.

Cheers

My explanation: The humidity was already there. When the bike cooled down in the back of the van to nearly 0 degrees Celsius, the relative humidity went up over the critical barrier. Is there any tutorial from other guys here, how to change the desiccant pack (descrition, pistures , Youtube video etc...) ?

First i will check data with MT and keep You posted, what the datas say.

Cheers