At 89 hours of motocross and despite no obvious reasons for which this should have happened (slight preload as per the 12 Nm specification, no rust, etc.), I've noticed that the outer race of my lower steering stem bearing has some shallow wear. The worn spots can't be felt by rubbing my fingertip but they can be felt by rubbing a plastic tool over them: the tool gets gently caught by them.

The handlebars turn smoothly without any play and I wouldn't know about those damages if I hadn't disassembled the bearings to re-grease them.

Surely the condition of that surface is not going to improve if I don't replace the bearing, so I'll have to do it. I'd like to replace at least the outer race on my own and I'd like to do it minimizing the risks of damages to the bike. I've never done this and I've read that it's usually a pain in the ass without the right tools.

• In order to remove the worn race, I was thinking of getting the Motion Pro Steering Head Race Puller, part no. 08-0737, since it seems like the best tool and it's not crazy expensive.

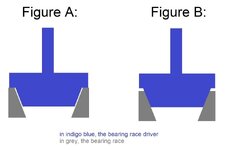

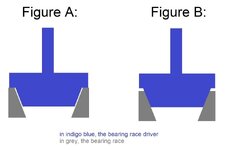

• Driving the new race into the frame seems more troublesome because I'd like to use a proper tool but the outer diameter of the bearings is 50.3 mm and I haven't found a race driver that is compatible with that dimension. Is the race driver supposed to contact the face of the bearing like in figure A or is its tapered surface supposed to push like in figure B? I guess figure A and that the tapered part of the driver exists only for centering reasons. In this case, a Ø50 mm tool may work because the tapered part wouldn't touch anything and hopefully the lip of the face would still be enough.

• For the part of the bearing installed on the stem, my plan is to simply bring it to a shop and have them replace it.

Any other suggetions or thoughts? I'd like to avoid tricks like utilizing the old race after having slitted it because I'd like to keep the components as square as possible.

The handlebars turn smoothly without any play and I wouldn't know about those damages if I hadn't disassembled the bearings to re-grease them.

Surely the condition of that surface is not going to improve if I don't replace the bearing, so I'll have to do it. I'd like to replace at least the outer race on my own and I'd like to do it minimizing the risks of damages to the bike. I've never done this and I've read that it's usually a pain in the ass without the right tools.

• In order to remove the worn race, I was thinking of getting the Motion Pro Steering Head Race Puller, part no. 08-0737, since it seems like the best tool and it's not crazy expensive.

• Driving the new race into the frame seems more troublesome because I'd like to use a proper tool but the outer diameter of the bearings is 50.3 mm and I haven't found a race driver that is compatible with that dimension. Is the race driver supposed to contact the face of the bearing like in figure A or is its tapered surface supposed to push like in figure B? I guess figure A and that the tapered part of the driver exists only for centering reasons. In this case, a Ø50 mm tool may work because the tapered part wouldn't touch anything and hopefully the lip of the face would still be enough.

• For the part of the bearing installed on the stem, my plan is to simply bring it to a shop and have them replace it.

Any other suggetions or thoughts? I'd like to avoid tricks like utilizing the old race after having slitted it because I'd like to keep the components as square as possible.