- Likes

- 2,480

- Location

- Charlotte, NC

Lately, I've been experimenting with some various shim stacks in the AER48 forks on my MXR to improve its performance (for me). I'll start documenting my journey and perhaps some of you may find it helpful in tweaking your own suspension and finding the best setting for you.

Don't be scared! With just a few simple tools you can do this yourself as well. The AER48's are very easy to work on. Technically, if you're careful, you can change the base valve damping on this fork without even having to remove the fork from the bike! Although, i wouldn't recommend it.

For reference, i'm 6'1, 190lbs naked, and now race B class here in Southern California. I ride strictly motocross and some supercross with my MXR, so these shim stack configs are purely focused on motocross riding using the stock AER48 base valve piston and mid valve piston. Other riding types and skill levels will require different styles of damping. If you weigh less or are less skilled, you would probably need softer than my settings. If you're heavier or more skilled, you may need stiffer.

Also keep in mind that all of this is based on my current shock configuration, as well. I'm currently running a 6.4kg/mm spring with 98mm of race sag, and slightly stiffer valving than stock.

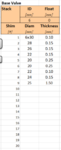

Stock Valving (-01 version AER48)

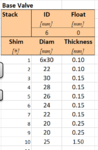

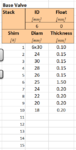

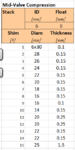

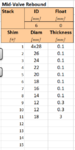

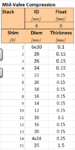

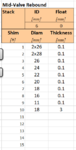

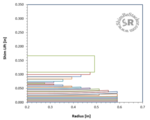

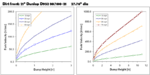

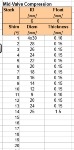

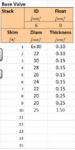

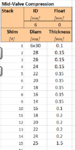

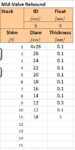

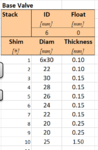

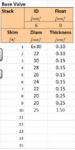

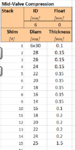

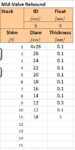

Shim Stack configuration:

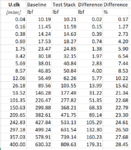

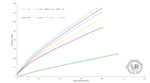

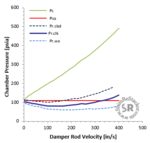

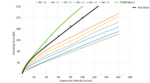

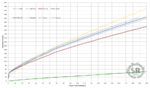

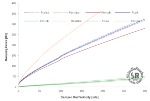

Compression damping chart:

(For reference, fork velocities in the 300in/sec range can be seen in motocross riding, and 350-400in/sec in supercross)

You can see that the stock damping curve on the AER48 on the MXR is digressive, a curve you often see with offroad setups.

The total compression damping (yellow) represents a combination between the damping provided by the base valve (green) and the mid valve (red) and minor elements from the rest of the system. You can see that the mid valve contributes much more to the total damping force than the base valve, but the importance of the base valve is pressure balance between the compression chamber (in front of/above the midvalve on compression) and the rebound chamber ("behind" the midvalve as its compressing) so as to prevent cavatation of the oil. This also means the rebound shim stack on the midvalve plays a very important part in pressure balance, as well. Also notice the dashed blue line represents the damping range as a result of the position of the compression clicker. (the yellow line represents clicker at 15 out).

This yellow line will be used as a baseline to compare to the rest of the shim stack configurations. This should help you all understand how much different the other configurations are compared to the stock setting that you probably are used to by now.

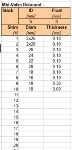

For reference, here are some key velocities and the damping force at those velocities for the stock stack:

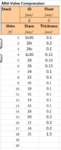

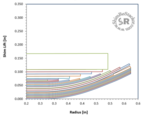

Pressure chart:

You can see that the stock valve stacks produce a pressure balanced system. A pressure drop to 0 on the rebound circuit would mean cavatation, and that's is not present. The ICS does a great job of keeping the pressure in the damping chamber on the positive side.

Personal Feedback:

The stock valving feels like it needs more damping across the board to handle big hits at the stock recommended air pressure of 10.8bar (156psi). Typically with air forks, higher pressure also means higher seal drag, which causes stiction that is most apparent in the first 1" or so of fork travel. The AER48 does much better than other air forks i've used, but its still an issue. As such, its always been my strategy with air forks use the least pressure possible that will allow the suspension to move even on small undulations but still provide deep stroke bottoming resistance, and then make up the rest of the feel by tuning the shim stacks.

Admittedly, i'm not so sure this is a good strategy to have. I think i should be taking the opposite approach, even with the air spring; Stiffer spring coupled with less overall compression damping to pair with it. More on that later...

Don't be scared! With just a few simple tools you can do this yourself as well. The AER48's are very easy to work on. Technically, if you're careful, you can change the base valve damping on this fork without even having to remove the fork from the bike! Although, i wouldn't recommend it.

For reference, i'm 6'1, 190lbs naked, and now race B class here in Southern California. I ride strictly motocross and some supercross with my MXR, so these shim stack configs are purely focused on motocross riding using the stock AER48 base valve piston and mid valve piston. Other riding types and skill levels will require different styles of damping. If you weigh less or are less skilled, you would probably need softer than my settings. If you're heavier or more skilled, you may need stiffer.

Also keep in mind that all of this is based on my current shock configuration, as well. I'm currently running a 6.4kg/mm spring with 98mm of race sag, and slightly stiffer valving than stock.

Stock Valving (-01 version AER48)

Shim Stack configuration:

Compression damping chart:

(For reference, fork velocities in the 300in/sec range can be seen in motocross riding, and 350-400in/sec in supercross)

You can see that the stock damping curve on the AER48 on the MXR is digressive, a curve you often see with offroad setups.

The total compression damping (yellow) represents a combination between the damping provided by the base valve (green) and the mid valve (red) and minor elements from the rest of the system. You can see that the mid valve contributes much more to the total damping force than the base valve, but the importance of the base valve is pressure balance between the compression chamber (in front of/above the midvalve on compression) and the rebound chamber ("behind" the midvalve as its compressing) so as to prevent cavatation of the oil. This also means the rebound shim stack on the midvalve plays a very important part in pressure balance, as well. Also notice the dashed blue line represents the damping range as a result of the position of the compression clicker. (the yellow line represents clicker at 15 out).

This yellow line will be used as a baseline to compare to the rest of the shim stack configurations. This should help you all understand how much different the other configurations are compared to the stock setting that you probably are used to by now.

For reference, here are some key velocities and the damping force at those velocities for the stock stack:

Pressure chart:

You can see that the stock valve stacks produce a pressure balanced system. A pressure drop to 0 on the rebound circuit would mean cavatation, and that's is not present. The ICS does a great job of keeping the pressure in the damping chamber on the positive side.

Personal Feedback:

The stock valving feels like it needs more damping across the board to handle big hits at the stock recommended air pressure of 10.8bar (156psi). Typically with air forks, higher pressure also means higher seal drag, which causes stiction that is most apparent in the first 1" or so of fork travel. The AER48 does much better than other air forks i've used, but its still an issue. As such, its always been my strategy with air forks use the least pressure possible that will allow the suspension to move even on small undulations but still provide deep stroke bottoming resistance, and then make up the rest of the feel by tuning the shim stacks.

Admittedly, i'm not so sure this is a good strategy to have. I think i should be taking the opposite approach, even with the air spring; Stiffer spring coupled with less overall compression damping to pair with it. More on that later...