Chadx

Well-known member

- Likes

- 223

- Location

- SW Montana

Inspired by others that have removed the Varg charger from the stand and moved it into a different case, thought I'd start a dedicated thread for this.

There are already some great images and info in the thread Poll: Are you using the original Stark Varg Stand/Charger as intended?

but thought someone searching might have an easier time finding a dedicated thread. And, I've not seen any pictures of taking it apart. Only the finished product, which gave me a false start becaue I first started taking off the bolts on the front of the charger rather than rear. Someone posted a link to a tiktok video, but I don't have a tiktok log in so couldn't watch it. In any case, home someone finds these pictures interesting.

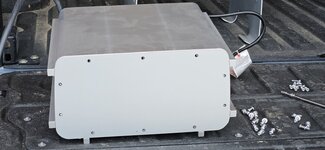

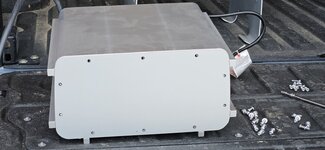

I started by removing the four larger bolts that hold the charge housing into the stand. But, like mentioned, I then started to remove the T30 bolts from the front of the charger housing only to find out it was unnecessary (and the two side ones are hard to get to because the bracket lips block access to the bolt head). Also noted those bolts didn't have any washers on them like the bolts on the back).

I put them back in and started removing the bolts from the rear of the charger housing. These had been installed through a black foam gasket and so punched out a sticky little bit of foam that stuck to the end of the bolt.

Then I removed the four bolts holding in the legs of the charger itself. The 240v cord easily pulled through it's opening as I pulled out the charger from the housing, but the bike charger connector could not fit through it's opening until the U shaped trim gasket was removed (see next post's images).

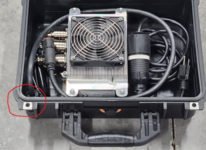

In images that others have moved these into a case, they don't have the silver/aluminum protector that is mounted to the fan in my below pics. Likely because that makes the charger too tall for the popular 6" tall cases that are used like the Harbor Freight 3800 and 4800 cases. With that shroud, my charger is over 7" tall.

Dimension of the charger itself, rounded to the nearest 1/2": 9.5"L x 9.5"W x 7"T.

I'm looking around for cases that are 8" or taller so I can keep on this shroud and stack the cords on top of that. Think I may have found one.

The Seahorse SW540. Interior: 13.5 x 9.9 x 8.4”

Seahorse SE540 Waterproof Protective Case (13.5 x 9.9 x 8.4”)

But at $76, it's about double the price of the Harbor Freight 3800 case, so maybe I'll just pull that shroud off to get it to fit in the HB 3800 or 4800 which have the following interior dimension:

HB Apache 3800: 14 7/8"L x 10 5/8"W x 6 1/8" T - $40 (regular price, but they do on sale a lot

HB Apache 4800: 17 7/8"L x 12 5/8"W x 6 1/8" T - $60

There are already some great images and info in the thread Poll: Are you using the original Stark Varg Stand/Charger as intended?

but thought someone searching might have an easier time finding a dedicated thread. And, I've not seen any pictures of taking it apart. Only the finished product, which gave me a false start becaue I first started taking off the bolts on the front of the charger rather than rear. Someone posted a link to a tiktok video, but I don't have a tiktok log in so couldn't watch it. In any case, home someone finds these pictures interesting.

I started by removing the four larger bolts that hold the charge housing into the stand. But, like mentioned, I then started to remove the T30 bolts from the front of the charger housing only to find out it was unnecessary (and the two side ones are hard to get to because the bracket lips block access to the bolt head). Also noted those bolts didn't have any washers on them like the bolts on the back).

I put them back in and started removing the bolts from the rear of the charger housing. These had been installed through a black foam gasket and so punched out a sticky little bit of foam that stuck to the end of the bolt.

Then I removed the four bolts holding in the legs of the charger itself. The 240v cord easily pulled through it's opening as I pulled out the charger from the housing, but the bike charger connector could not fit through it's opening until the U shaped trim gasket was removed (see next post's images).

In images that others have moved these into a case, they don't have the silver/aluminum protector that is mounted to the fan in my below pics. Likely because that makes the charger too tall for the popular 6" tall cases that are used like the Harbor Freight 3800 and 4800 cases. With that shroud, my charger is over 7" tall.

Dimension of the charger itself, rounded to the nearest 1/2": 9.5"L x 9.5"W x 7"T.

I'm looking around for cases that are 8" or taller so I can keep on this shroud and stack the cords on top of that. Think I may have found one.

The Seahorse SW540. Interior: 13.5 x 9.9 x 8.4”

Seahorse SE540 Waterproof Protective Case (13.5 x 9.9 x 8.4”)

But at $76, it's about double the price of the Harbor Freight 3800 case, so maybe I'll just pull that shroud off to get it to fit in the HB 3800 or 4800 which have the following interior dimension:

HB Apache 3800: 14 7/8"L x 10 5/8"W x 6 1/8" T - $40 (regular price, but they do on sale a lot

HB Apache 4800: 17 7/8"L x 12 5/8"W x 6 1/8" T - $60