@Lvproj just wanted to point out the effective differences.

Fork:

View attachment 12522

The two .30x15 shims at the bottom of your LSV stack are acting as spacers since they are larger than the smallest shim. We effectively have very similar LSV's with a 12mm clamp shim. Mine is slightly stiffer with the 19 and 17 added in.

Your base valve stack is much softer overall, with a 16mm clamp and less face shims compared to my 20mm clamp.

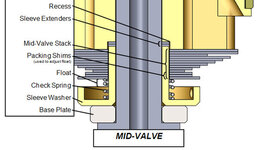

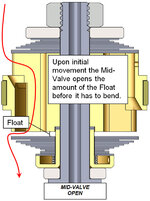

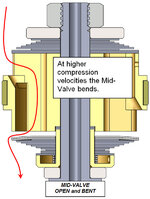

Your mid valve stack is much softer as well, but not for the reasons you highlighted. The 6mm ID shims are just spacing shims to set the float on the compression stack. My stack is single stage vs your two stage (more digressive) and has more face shims. We both have 10mm clamp shims but your 0.40mm of float makes the overall compression damping much softer than mine.

Same rebound stack on the midvalve which is interesting because i'm running much stiffer springs than you.

Shock:

View attachment 12523

Your shock compression stack is softer with less face shims , a thicker crossover shim, and a smaller 21mm clamp shim vs my 22.

Your rebound stack is softer as well and that makes sense since i'm running a much stiffer spring which requires more damping to tame .You also have a larger rebound separator bleed by 0.3mm which further softens the rebound circuit overall.

After an initial ride on the setup , I feel like i need a little more compression damping in the front and quite a lot in the rear, and the rebound doesn't rebound quick enough. I'll be tearing the forks and shock apart again to make the following changes:

LSV: step up to 13mm clamp.

Base Valve Comp: step up to 21 clamp and add a .10x30 face shim.

Mid Valve Comp: change the .30x10x8 clamp to a 0.30x12x8 clamp. Keep float at 0.25mm.

Shock Comp: remove the .25x22 clamp (to step up to a 24mm clamp) and add a .25x44 face shim.

Shock Rebound: remove one face shim for less/quicker rebound.