DonCox

Well-known member

- Likes

- 647

- Location

- Lake Havasu City, AZ

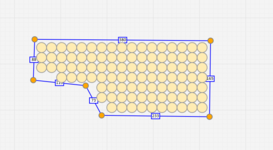

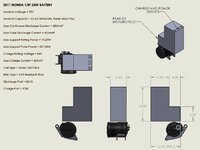

I don't want to bad mouth Eon Lithium , but we have bought a few batteries from them, and have not been real happy. Bob knows Raymond there at EON Lithium real well, and has one of his batteries, and I put one in one of my customers bikes, and were not real keen on them. The battery you are looking at is with Samsung 50S cells, yes if you were trail riding, it would be OK, but 300A max will be weak, and if your battery is over 300A you want a QS10 Anti spark output connector. The Amorge folks can and will build to your spec. Cells are an expensive part of the equation. The video I sent you gives some pricing, but roughly the Molicel P42A, (4200mah 45AH)is about $4.50 a cell, Lishen LR2170LA(economy cell) will give you 4000mah and 35AH, but with some heat. The Samsung 50S about the same price as the Molicel P42A, but 5000mah and 45ah, but create more heat ( higher resistance). Then there are the Molicel P45B, and the P50, which are all better. P45B is what the Stark is using, and more expensive, and then the P50B which is better , but way more expensive. We have put 20S12P in the Honda frame, if you are designing for and with a quick change battery in mind this is the good size. If you could get a 20S14S or 16S battery in a CRF frame with the Molicel P45B or P50B cells you would have the range and the Power you need. You want the 40A charge BMS , but you need to have the power side Open Discharge, or no BMS control. ( to reduce heat in the battery box, since the controller has low voltage control. The battery is the most complicated part of the build.

![IMG_7265[1].JPG IMG_7265[1].JPG](https://electricdirtriders.com/data/attachments/12/12115-0049c8c2e4a6748f54dae6b131780d97.jpg?hash=AEnIwuSmdI)

![IMG_7266[1].JPG IMG_7266[1].JPG](https://electricdirtriders.com/data/attachments/12/12116-fcd63ff618cf9cfe4443eae2a8f2bd03.jpg?hash=_NY_9hjPnP)