Jim Beagle

Well-known member

- Likes

- 55

- Location

- Placida, Florida

Well, in my case i don't have a twin spar frame to fit it in so i guess we'll see what happens!Hello halg

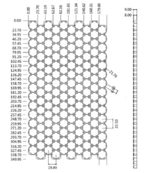

here is the file that Amorge sent me, when I scaled it up to 100%, I did notice that the dimensions in one direction were off just a millimeter or two from the other direction, but I think it really helps to look at a design and see how the impact of tweaking various custom angles of the box can affect cell count

I looked thru the various "standard" battery dimensions, and it seems that the width (side to side in the bike) for a two stack pack is between 155mm & 160mm. Several of their standard packs have with these dimensions. Amorge did confirm with my Original pack design would be 155mm. I have not yet received a width confirmation from them on my buffalo three stack pack, but I did see Don Cox had one built that was 9 inches wide

I really believe a pack between the frame rails is safer overall, but if I go with the wider side loaded pack, maybe I can build some box rails to offer a bit of protection......

View attachment 13149

I'm having trouble following all that and it seems like you are as well. Maybe after some coffee I can process better.my Amorge journey continues....

so I sent the 'Buffalo v2" battery design to Amorge, Miranda comes back and says:

Hello, friend

We checked the size of your battery.

The 332MM position we drew only 323MM

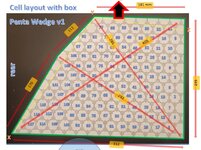

According to the frame size of this battery, we calculated that there are 108 battery cells in total

In addition, if you need to make three layers, the size of the three layers is 235MM

In addition, this battery is a custom size, and the current size is not suitable for making a metal box.

In addition, you change the size of the battery to a rectangular shape, which is easier to make a metal box

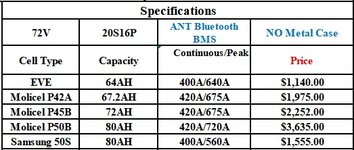

I wasnt really surprised that they couldnt build a box with that many sides, and I was thinking maybe I could build my own, and good news she did confirm the width of three layer is 235mm and 108 cells. So I am thinking great 108 X 3 = 324 so they can do 20S16P. My sketch was 112+, so I am wondering if maybe I can pull in a couple of sides just a bit and give more clearance to the bike frame, and still have 108. So I asked how they came up with 108. She sends pic below with four cells crossed out, again I am thinking no worries. So I ask this question: What are the specifications for a 20S16P using Molicel P45B cells

and Miranda responds:

According to your requirement, 20S16P cannot be made.

The largest battery can be made to 20S15P

Because it is made by using three layers of batteries, then one layer has 7S, which is 16*7=112 battery cells, which has exceeded the battery size we calculated.

Making 20S15P is 105 cells, which is possible

Now I had 112+ cells in my layout, so I dont follow her 7S math above at all. and 20S15P should be 100 cells per layer not 105.

so here is where I am looking for experienced battery builders knowledge

can a three layer pack, share one set of 20S cells between the layers ?

100 + 110 + 110 = 320

or

107 + 107 + 106 = 320

Note: all of this has me seriously considering to just lower my expectations to 20S 15P, then shrink the size of a layer down to 100 cells,

and possibly simplify the pack shape, so they can build me a box........

appreciate the advice THANKS !!!

View attachment 13188

I'm confused by this question and I'm not sure how two discharge cables would work in an actual build. Does requesting open discharge mean this is a non question? How is @DonCox pulling 400 amps if she says there is no connector capable? Is this simply incorrect?Miranda also says: Regarding the output cable, we recommend that you use a dual QS10 connector so that you can fully utilize the continuous current you need. Because no connector can fully use the continuous current of 400A. The cable on my battery is 20CM, and the normal one we provide is a 25CM ring terminal. I will need to check these lengths,

any other advice here ?

Just to answer your question, I typically do have 2 QS10 connectors, or on earlier bikes 2 Anderson connectors. For Performance bikes, bikes that guys are going to run hard, I split the battery to take advantage of 2 chargers, and share the output load, one for each 1/2 pack. But that also requires 2 BMS's inside the battery, and 2 sets of QS10 output cables. Allen at Amorge has recommended that I put 2 chargers onto one larger BMS for faster charging, but I would recommend going with 2 QS10 connectors for the higher current batteries, as your agent at Amorge stated. The 20S12P P45B celled battery can put out almost 500A, and your 20S16P can put out 650A. The KTM I built almost 3 years ago with the 20S16P battery is split in 2 for charging and for output with 2 Anderson connectors going to a Dual Battery switch where you can select one or the other or both batteries. I have used #6 wire from these batteries, and #4 wire off the dual battery switch to the controller. I use the same setup on my current KTM with a home built split battery. The bike KTM I recorded here on this forum ( 2019 KTM 450SXF Factory Edition Conversion to Electric Street Legal) does not have a split battery, nor 2 output connectors, because this is not for an aggressive rider, but I think I am going to in future builds, going to that model of 2 Charge cables and 2 discharge cables. Amorge did put #4 cables on the QS10 connector on the 2019 KTM I built, it was in the quote.I'm confused by this question and I'm not sure how two discharge cables would work in an actual build. Does requesting open discharge mean this is a non question? How is @DonCox pulling 400 amps if she says there is no connector capable? Is this simply incorrect?

I wouldn't split the connectors that way. There is an antispark resistor in the connector, that does help. There is also a label on the connector for + an- . I would wire them correctly, but just have 2. Your second statement is correct, I set my controller to go to Limp mode ( Votol Soft Undervoltage) at 65V and off at 59V for a 72V nominal system.Halg

I could be wrong here, but I think Miranda Amorge is planning one QS10 for B+ and another for B-

BMS are capable of monitoring cells during both charge and dis-charge. From what I have read, many builders "bypass" this function during operation to reduce heat, and just set the Controller voltage parameters to protect the pack.

Others may offer additional information

Thanks so much for this information. After some measurements this weekend it looks like I am going to be able to fit ~300 cells (320 if I am lucky) in this frame. I'll be posting more in a follow up thread. But, regardless, this is entering territory where, based on the information provided here, I may reach the threshold of needing to split charging & discharging. Much to process that I'm unable to do right now but thanks again for sharing.Just to answer your question, I typically do have 2 QS10 connectors, or on earlier bikes 2 Anderson connectors. For Performance bikes, bikes that guys are going to run hard, I split the battery to take advantage of 2 chargers, and share the output load, one for each 1/2 pack. But that also requires 2 BMS's inside the battery, and 2 sets of QS10 output cables. Allen at Amorge has recommended that I put 2 chargers onto one larger BMS for faster charging, but I would recommend going with 2 QS10 connectors for the higher current batteries, as your agent at Amorge stated. The 20S12P P45B celled battery can put out almost 500A, and your 20S16P can put out 650A. The KTM I built almost 3 years ago with the 20S16P battery is split in 2 for charging and for output with 2 Anderson connectors going to a Dual Battery switch where you can select one or the other or both batteries. I have used #6 wire from these batteries, and #4 wire off the dual battery switch to the controller. I use the same setup on my current KTM with a home built split battery. The bike KTM I recorded here on this forum ( 2019 KTM 450SXF Factory Edition Conversion to Electric Street Legal) does not have a split battery, nor 2 output connectors, because this is not for an aggressive rider, but I think I am going to in future builds, going to that model of 2 Charge cables and 2 discharge cables. Amorge did put #4 cables on the QS10 connector on the 2019 KTM I built, it was in the quote.